Re: Surface Mount Soldering Techniques

Posted by Karlis on Mar 03, 2016; 5:59am

URL: http://bluesaab-forum.90.s1.nabble.com/Surface-Mount-Soldering-Techniques-tp250p257.html

Here are my two cents. :)

The most important thing is that surface mount soldering takes practice. I learned it the hard way after ruining like four PCBs and a number of bluetooth chips. My rule of thumb is to be generous with flux. Then when applying solder, the PCB tends to take just as much solder as it needs. The excess flux then can be cleaned off with isopropyl alcohol. Another thing to keep in mind is to have a good soldering iron running at ~350C. Also the tip of the soldering iron has to be clean at all times when soldering. That saves a lot of hassle and pain. I'm using a wire mat to clean the tip, but I know people also use a wet sponge to do the same.

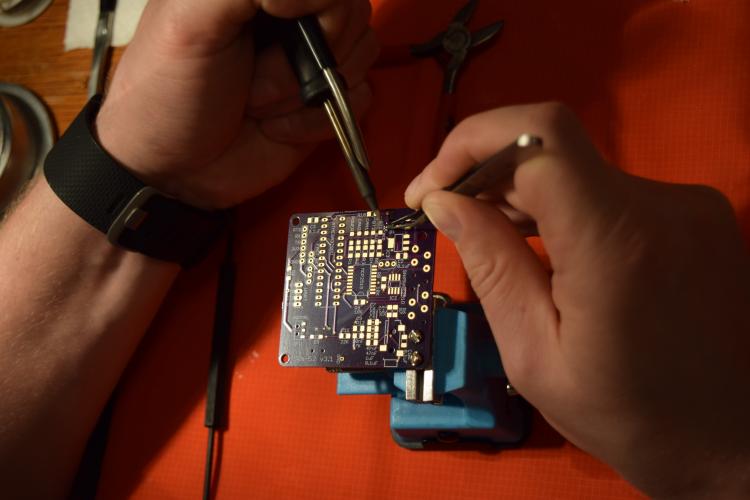

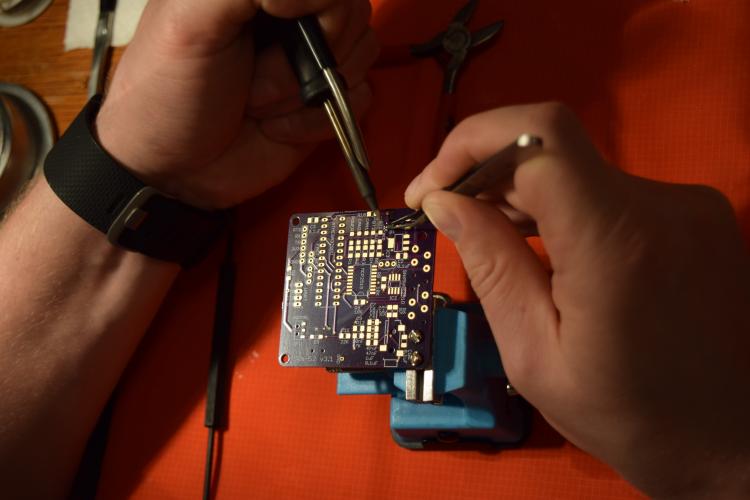

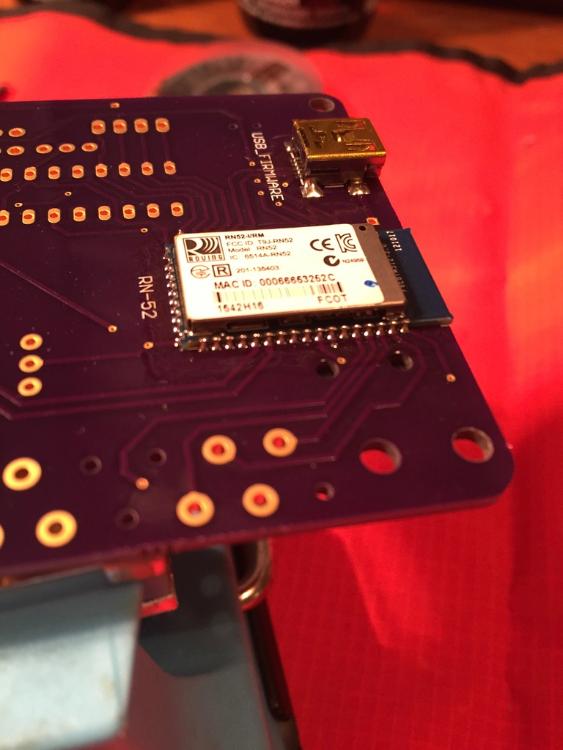

As for the parts placement, I'm using small tweezers. Then hold them steadily as possible and do a small tap with the soldering iron. That will hold the part in place. Here's a pic from the process:

In order to solder chips in place, I tap one of the pins in place and then (after applying another round of flux) I use the "drag" method.

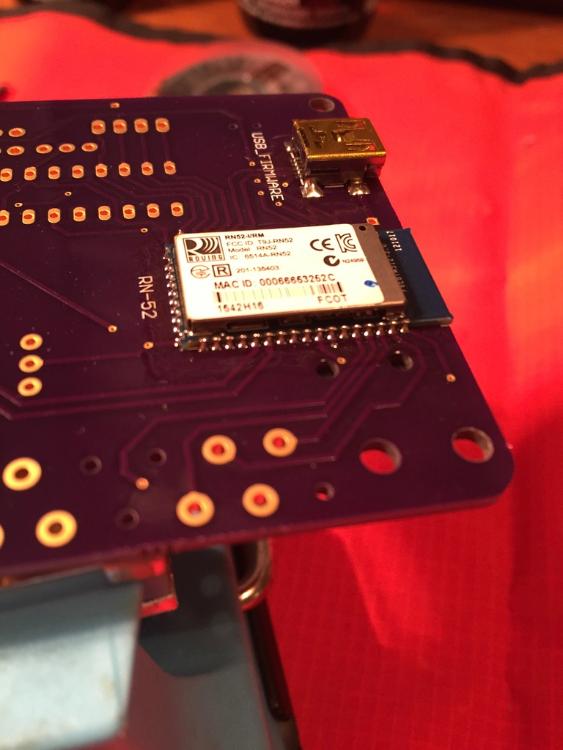

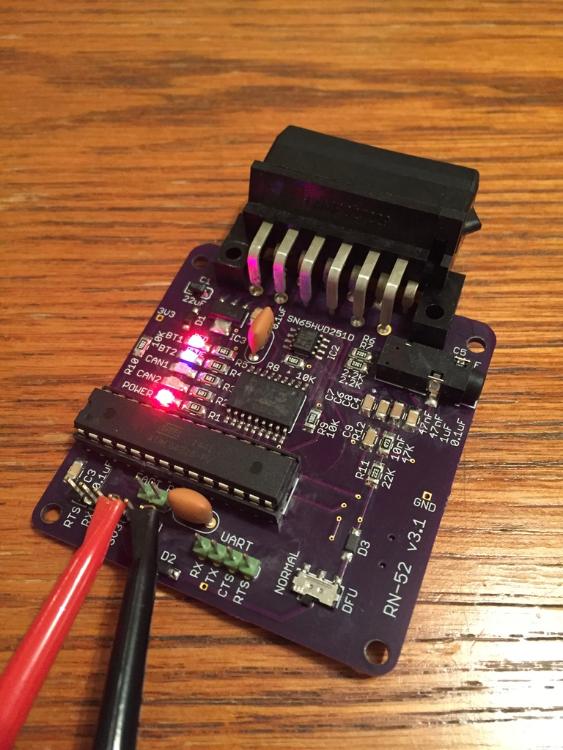

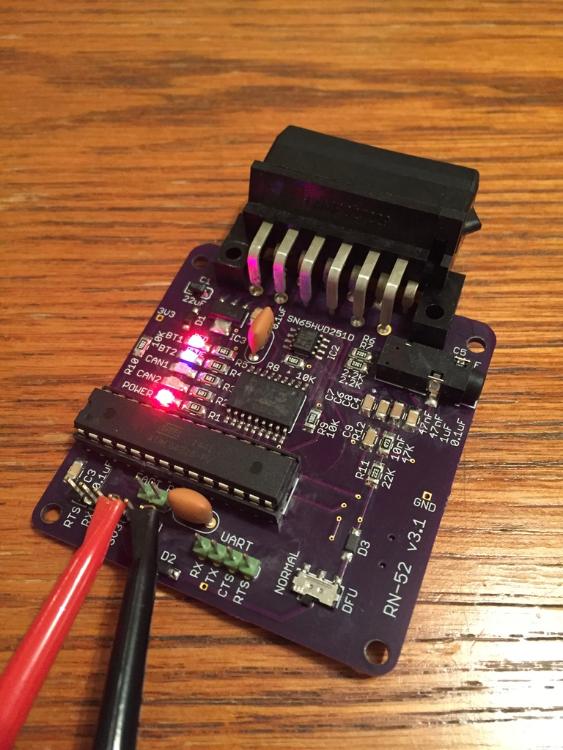

The end result :

:

URL: http://bluesaab-forum.90.s1.nabble.com/Surface-Mount-Soldering-Techniques-tp250p257.html

Here are my two cents. :)

The most important thing is that surface mount soldering takes practice. I learned it the hard way after ruining like four PCBs and a number of bluetooth chips. My rule of thumb is to be generous with flux. Then when applying solder, the PCB tends to take just as much solder as it needs. The excess flux then can be cleaned off with isopropyl alcohol. Another thing to keep in mind is to have a good soldering iron running at ~350C. Also the tip of the soldering iron has to be clean at all times when soldering. That saves a lot of hassle and pain. I'm using a wire mat to clean the tip, but I know people also use a wet sponge to do the same.

As for the parts placement, I'm using small tweezers. Then hold them steadily as possible and do a small tap with the soldering iron. That will hold the part in place. Here's a pic from the process:

In order to solder chips in place, I tap one of the pins in place and then (after applying another round of flux) I use the "drag" method.

The end result

:

:

2001 9-5 SE V6; 2006 9-5 Wagon; iOS; BlueSaab version = "latest and greatest" :)

| Free forum by Nabble | Edit this page |