Surface Mount Soldering Techniques

|

Mods feel free to move this, I just figured I'd post some things I found useful that may help beginners like myself on this project....

So I have soldered a decent amount of things from guitar electronics to car wiring harnesses and even some other PCB boards before but I had never done anything with surface mount pieces as used on the BlueSaab adaptor, it had always been through-hole soldering. I quickly found that it was a little different and required a third arm to coordinate holding the piece in place, using the soldering iron, and applying the solder. I ended up damaging a few capacitors trying to do this and decided I needed a new approach. After a bit of googling it seems like there are some things that would make it a little easier. I ended up ordering some solder paste, which sort of dispenses like toothpaste and lets you apply some solder to the pads and the cap/resistor/etc and frees up a hand to hold the piece in place while you solder. This is what I chose but there are many options out there: http://www.amazon.com/MG-Chemicals-4900P-25G-Solder-Silver/dp/B00XYB73MU And then I watched a few videos for some techniques on how to apply the paste. For the big pads for capacitors and resistors I applied a little dot of paste on the pad and then on the component as well, you have to be a little careful not to put too much as the paste spreads out a bit when you heat it. For the chips I did what they show in this video, put the chip in place and then run a bead across the pins on the board and then heat with the iron and the solder will wick up from the board onto the pins. https://www.youtube.com/watch?v=5uiroWBkdFY This all may be painfully obvious for anyone who has done projects like this before but I just figured I'd share it in case anyone else is unsure how to begin with the BlueSaab project as I was. |

|

Administrator

|

Here are my two cents. :)

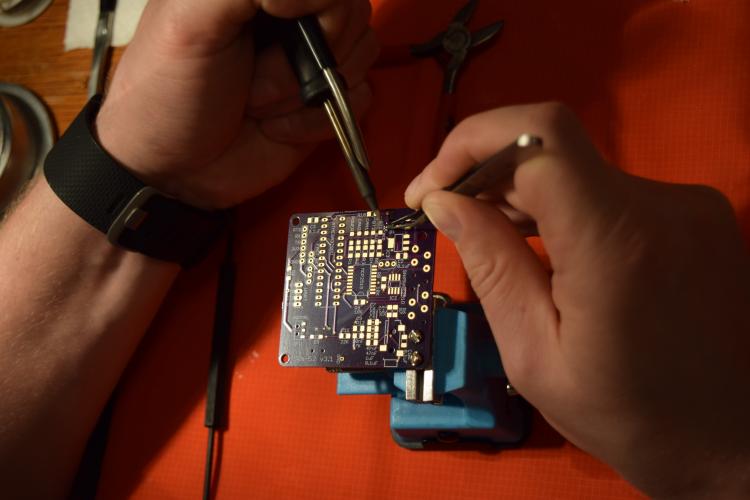

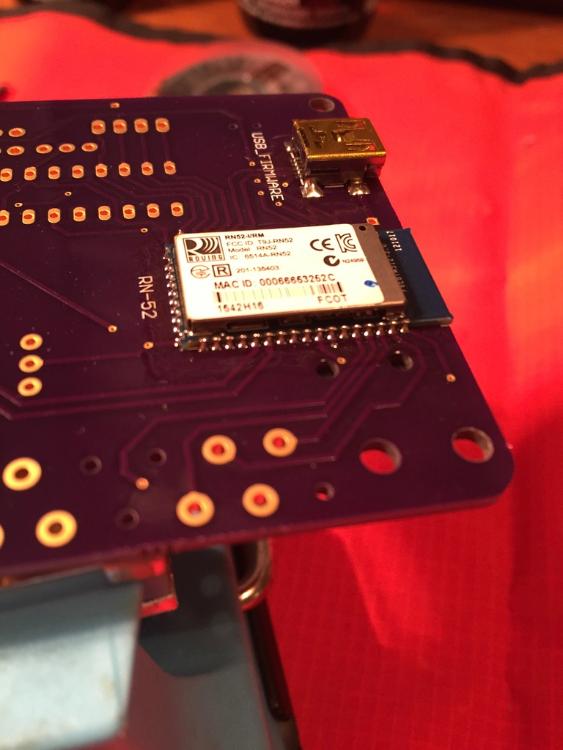

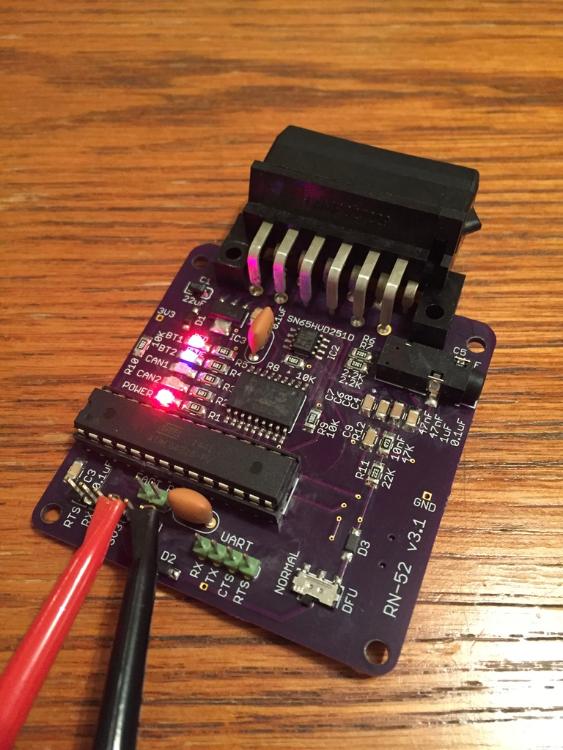

The most important thing is that surface mount soldering takes practice. I learned it the hard way after ruining like four PCBs and a number of bluetooth chips. My rule of thumb is to be generous with flux. Then when applying solder, the PCB tends to take just as much solder as it needs. The excess flux then can be cleaned off with isopropyl alcohol. Another thing to keep in mind is to have a good soldering iron running at ~350C. Also the tip of the soldering iron has to be clean at all times when soldering. That saves a lot of hassle and pain. I'm using a wire mat to clean the tip, but I know people also use a wet sponge to do the same. As for the parts placement, I'm using small tweezers. Then hold them steadily as possible and do a small tap with the soldering iron. That will hold the part in place. Here's a pic from the process:  In order to solder chips in place, I tap one of the pins in place and then (after applying another round of flux) I use the "drag" method.    The end result  : :

2001 9-5 SE V6; 2006 9-5 Wagon; iOS; BlueSaab version = "latest and greatest" :)

|

«

Return to Essentials

|

1 view|%1 views

| Free forum by Nabble | Edit this page |